Drilling Holes in Foam at "Kalrail" Rick Fletcher - NSW Australia |

Updated 25 June 2016

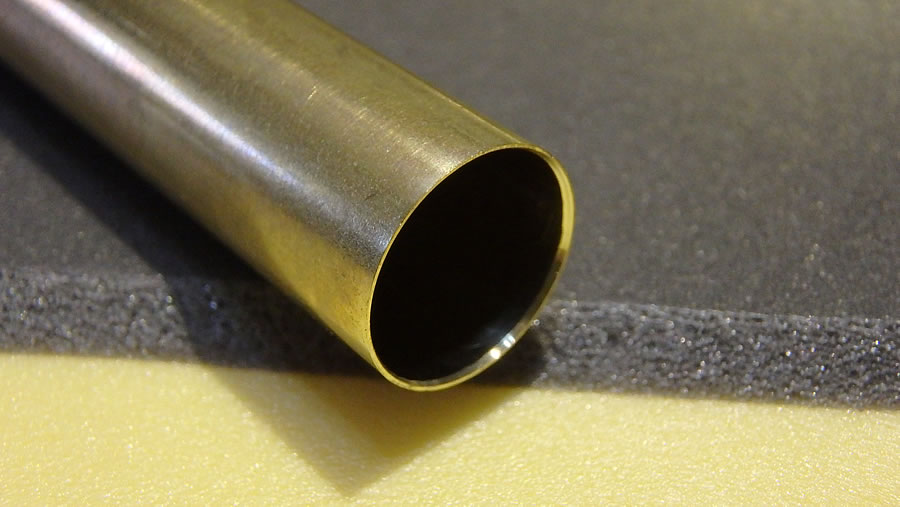

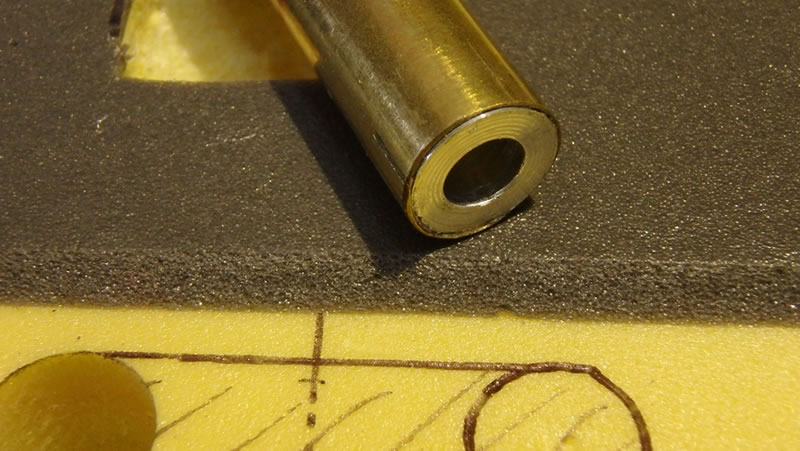

Prepare the cutting edge by bevelling the end of the tube on the INSIDE. I carry out that operation on a lathe using a scraping tool but it could be done in a drill for short tube drills. It may even be possible to use a tapered reamer to form the bevel. There may be a need to touch-up the edge from time to time.  |

||

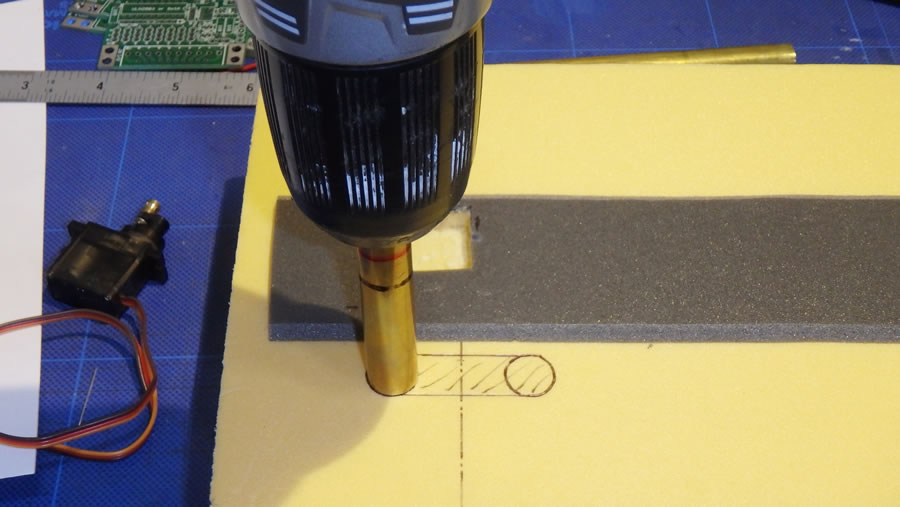

Use a hand drill on a fast speed. This 12mm hole is through 50mm foam to fit a micro servo (eg Tower Pro SG90 or my preference Micro 9g Metal Gear Servo)  |

||

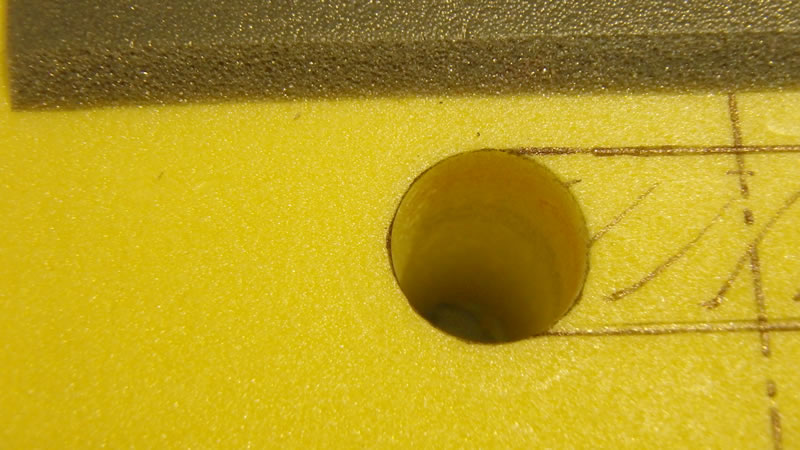

The result is a very clean hole |

||

For 12mm brass tube it is necessary to reinforce the end held in the drill to prevent crushing. I machined a small piece of aluminium in the lathe (about 20mm long) and epoxied it into the top end. A hole is necessary through the middle so you can use something to push the waste foam out. You could use a tube of plastic or wood the right size or file it down in a drill. Or fill the end with epoxy and drill a hole.  |

||

Push the waste out. |

||

|

||

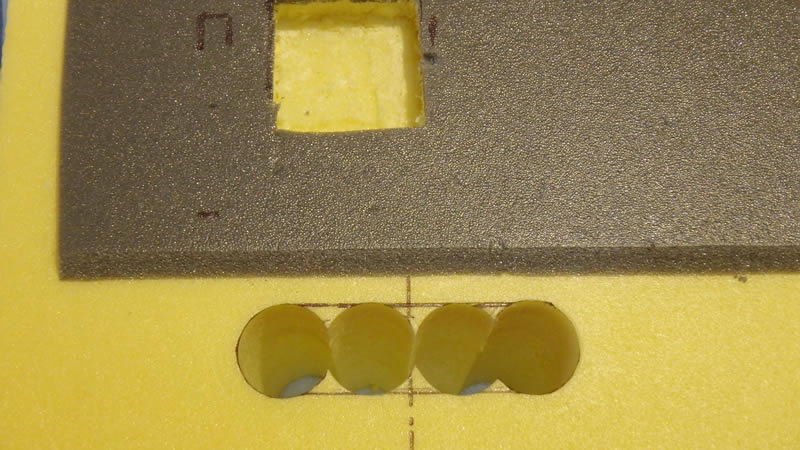

| Here 4 holes have been quickly drilled to accept a servo with minor trimming. MORE DETAILS ON MOUNTING SERVOS IN 50mm XPS FOAM - COMING SOON  |

||

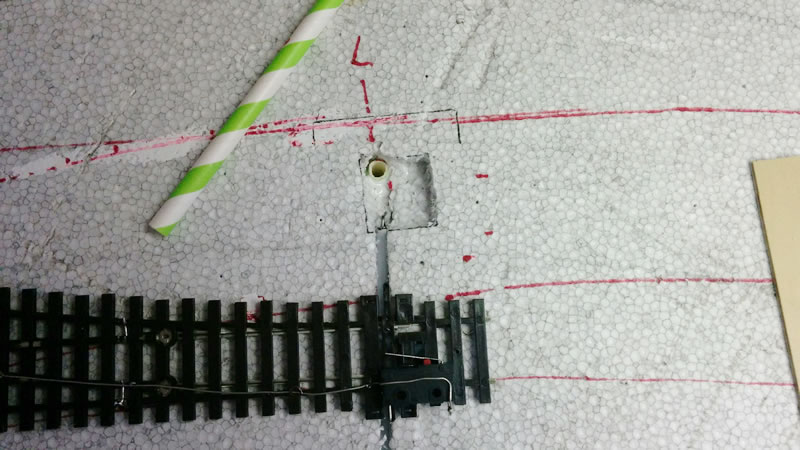

| In this photo a hole was drilled under a point to carry the wiring from the micro switch under the layout. Note the use of a length of paper drinking straw to line the hole so that the chemicals in the foam don't attack the wire insulation. The straw is held in place with a dab of PVA woodworking glue or similar.  |

||

|

||

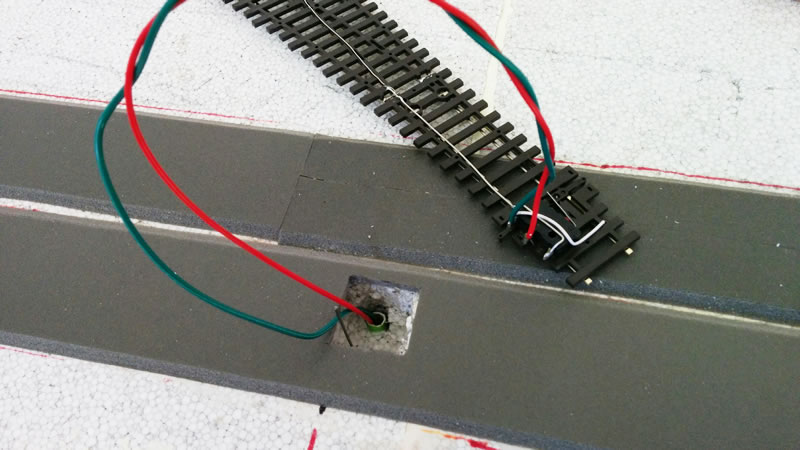

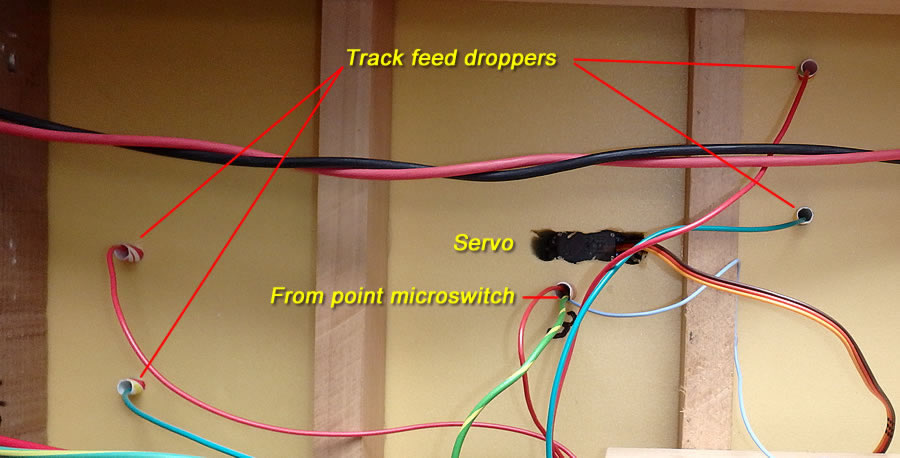

| This is the underside of the layout showing five 6mm holes, lined with a drinking straw, to carry track feed droppers. The centre 6mm hole carries 3 wires from the microswitch fitted to the point. The 4 x 12mm overlapping holes have accommodated the micro servo and its connecting wire.  |

||

| These are the drills I have prepared. The 2 on the left are 6mm (OD) with the longer one used to go through 200mm of foam and the shorter one for all of the feed wire droppers. The 6mm Brass tube does NOT require reinforcing in the end where it is held (but don't overdo the chuck). The next two are 12mm which is the exact thickness of the micro servos. The long one goes through the 120mm foam sheets I have used (not recommended) and the shorter one for the extruded 50mm foam. This is used for the servos.  |

||

Working Expanded Styrofoam (EPS) can produce a SNOW STORM!! Brilliant for working up under a layout. My suitcase type vacuum came from a local chain store (BigW in Australia).

|

||